- Sealing agent

CRAINE 210

-

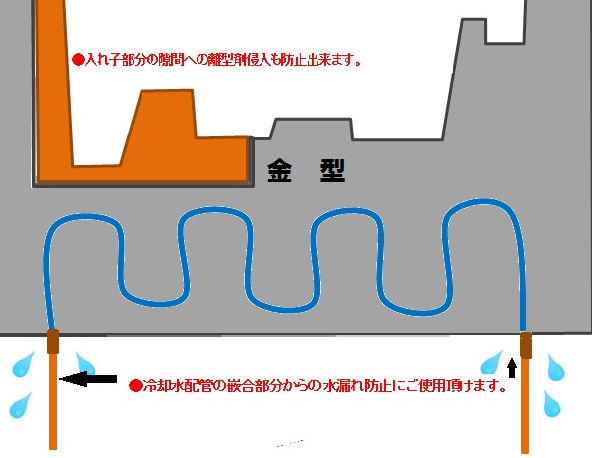

- Waterproof agent for steel mold

- Undiluted liquid concentrate, paste type

- Heat proof up to 450. Water proof and close adherence

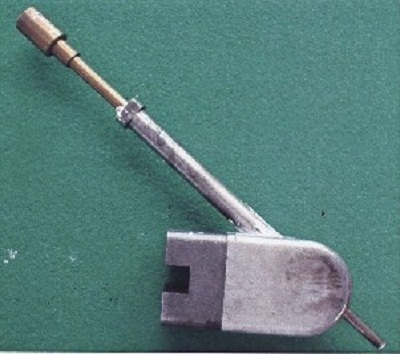

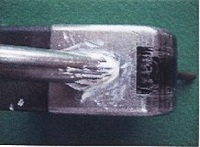

Sealing agent for steel mold "CRAIN 210" photos in use.

How to use

1) clean the face with waste cloth before coating

2) coat thinly and attach

- Use

- Sealing agent for steel mold should be heat resistance, water resistance, low solidity but the products currently on the market does not reply to their requirement.

Our product, CRAIN 210 is produced to reply the market demand.

CRAIN 210 completely protect from water permeate and maintain good performance for long time. This agent easily take off from the mold due to low solid adhesion. - Feature

- 1. Can maintain good performance at high temperature at 350-400

2. Can keep strong water resistant, hot water resistant for long time

3. will not adhere the molding film hence easy to release

4. CRAIN 210 will create the hardened body by thermal reaction. The hardened body will not softened by heat.

5. CRAIN 210 create strong layer hence shows excellent water proof effect.

6. This is paste type and can coat thinly. - usage

- 1. Clean the face with waste cloth before coating

2. Apply Crain 210 by thinly coating to the damaged area.

3. Heat the steel mold at over 170 and keep it for 30-60 min.

Repair agent will be hardened and seal the damage completely. - Property

-

Appearance Light yellow paste Density15 g/cm3 1.98 - 2.02 Solubility Insoluble by water - Remarks

- 1. Please brash wash with water and detergent if it attach on hands.

2. Close the cap tightly after use and keep it at room temperature

3. When open the cap, the brown liquid may appears but no influence on quality. - Package

- 200g tube X 6 per case